Industrial Lifting

Osra Special Parts:

Your Partner for…

Each machining operation is performed with advanced technology and high quality standards, ensuring optimal results, reliability and precision. Discover in detail all our capabilities within this page and trust Osra for your next industrial challenge.

Industrial Lifting

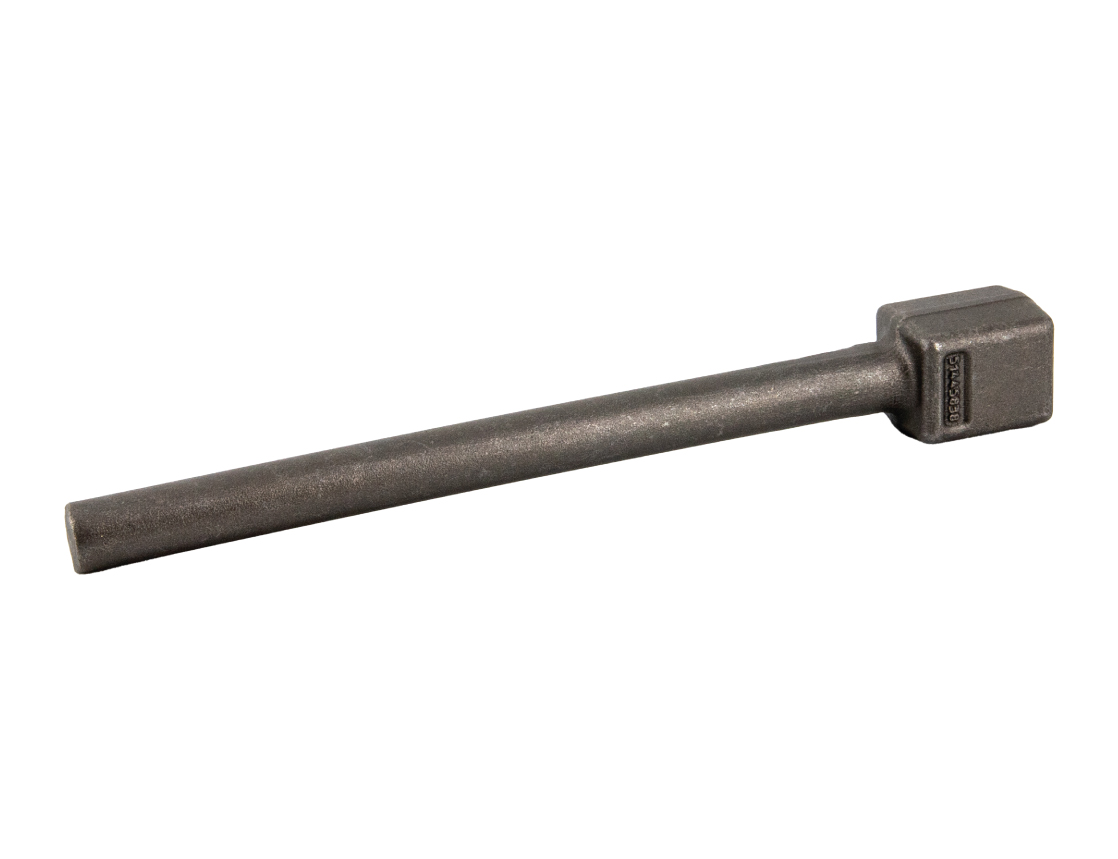

Hot forging

Hot forging is a process that uses heat and pressure to form metals into complex, strong parts. At Osra Special Parts, this technique enables the production of high-quality components for earthmoving and lifting sectors.

Using this method, we can work with different metals and ensure solutions tailored to our customers’ needs. Our advanced technology ensures uniform and long-lasting results while maintaining a high standard of quality at all times.

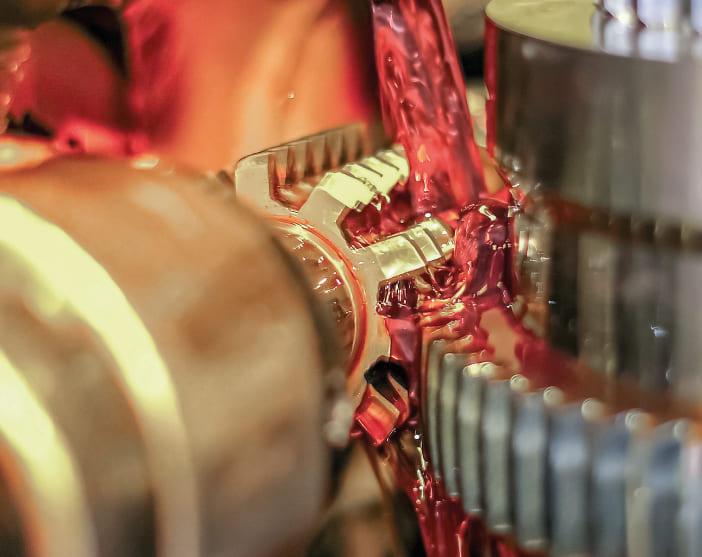

Electro upsetting

Electro upsetting is a manufacturing process that uses electric current to heat and deform metals precisely. This technique, adopted by Osra Special Parts, allows us to obtain high quality components with tight tolerances, ideal for sectors that require maximum precision such as lifting and automotive.

Thanks to electro-upsetting, we can work with different materials, offering tailor-made solutions to meet the specific needs of our customers. Our advanced technology guarantees reliable and uniform results, always maintaining high quality standards.

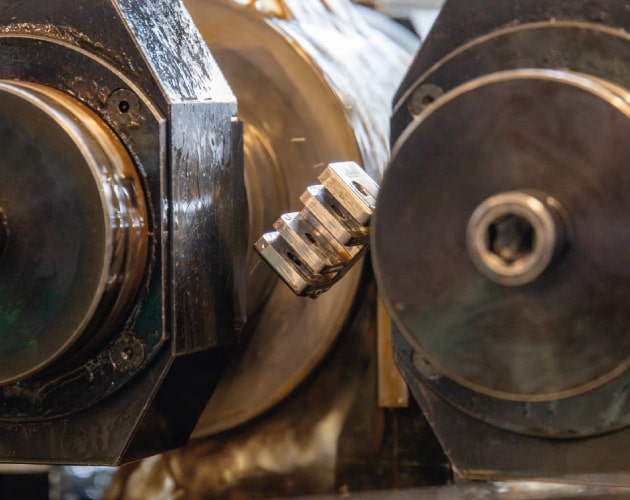

From solid bar

Solid bar machining is a process that uses solid metal bars to create highly precise, custom components. At Osra Special Parts, this technique allows us to produce complex and robust parts, ideal for a wide range of industries, including automotive, pharmaceutical and precision engineering.

Using advanced machinery, we can work with various metals and alloys, ensuring tailor-made solutions that meet the specific needs of our customers. Our attention to detail and rigorous quality control ensure consistent, reliable results, always maintaining the highest standards of excellence.