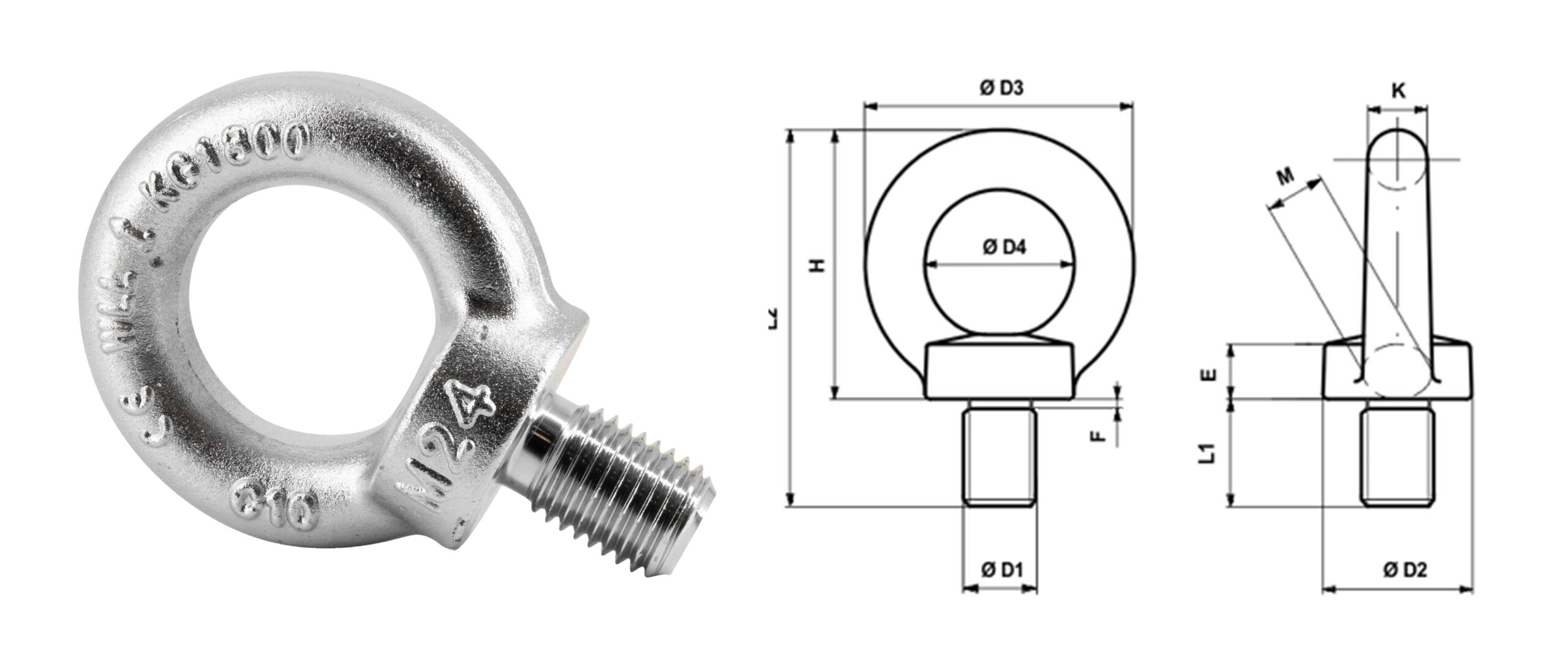

Lifting Eye bolts

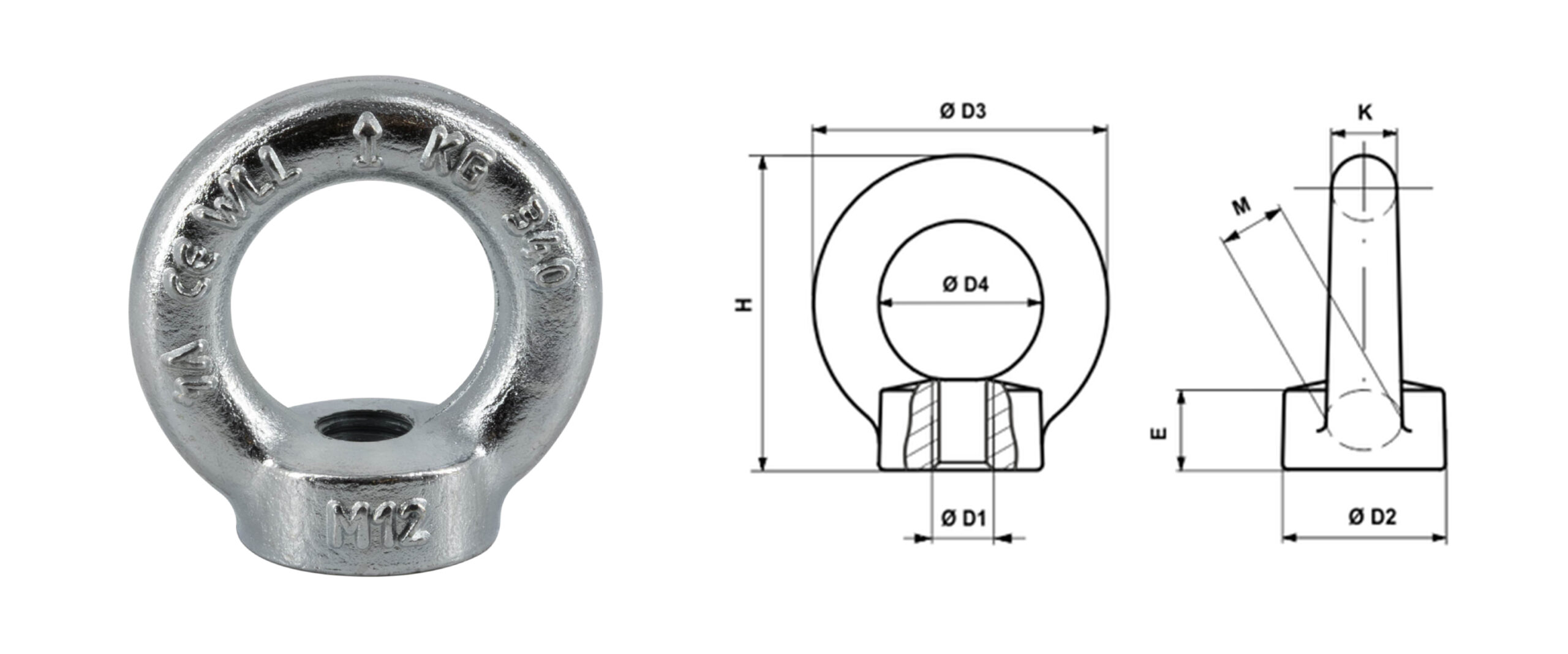

Lifting Eye nuts

Reliability And Safety In Lifting

Community Directive EN 2006/42/EC defines eyebolts as lifting accessories. “Lifting accessories are components or equipment not connected to lifting machinery, which enable the load to be picked up, either arranged between the machine and the load or on the load itself, or intended to become an integral part of the load and to be placed on the market separately; slings and their components are also considered lifting accessories.”.

The following information must be clearly and indelibly marked on the eyebolt: material abbreviation, load capacity in kilograms (WLL - Working Load Limit) at straight pull, arrow with the direction of pull relative to the indicated capacity, manufacturer's abbreviation, thread size, CE mark in the prescribed form, batch of manufacture. Each lifting accessory must be accompanied by operating instructions (mandatory for safety regulations) containing at least the following information: intended use, limits of use, directions for assembly for use and maintenance, static test coefficient used. As a guarantee of compliance with the safety requirements of the product, in addition, it is necessary to provide the EU certificate of CE conformity, signed by a natural person as the legal representative of the Manufacturer (or his delegate).

The following information must be clearly and indelibly marked on the eyebolt: material abbreviation, load capacity in kilograms (WLL - Working Load Limit) at straight pull, arrow with the direction of pull relative to the indicated capacity, manufacturer's abbreviation, thread size, CE mark in the prescribed form, batch of manufacture. Each lifting accessory must be accompanied by operating instructions (mandatory for safety regulations) containing at least the following information: intended use, limits of use, directions for assembly for use and maintenance, static test coefficient used. As a guarantee of compliance with the safety requirements of the product, in addition, it is necessary to provide the EU certificate of CE conformity, signed by a natural person as the legal representative of the Manufacturer (or his delegate).

Discover the features of our lifting Eye bolts/nuts

Explore our wide range of eyebolts, available in male and female versions, to meet all your lifting needs. Our eyebolts are manufactured according to DIN580 and our eye nuts according to DIN582 standards: you have the assurance of a controlled and certified product!

Discover our solutions

Standard Solutions Compliant with CE Standards

- Compliant with CE Standards

- Always accompanied by operating instructions.

- With EN10204 2.2 certificate (On request)

- Coded GLM (eyebolt) and GLF (eyenut)

Exclusivity with 100% Made in Italy Products

- Compliant with CE regulations

- Always accompanied by instructions for use.

- With EN10204 3.1 certificate (On request)

- Certificate of product origin

- Coded MECGOLM (DIN580:2018) and MECGOLF (DIN582:2018)

Materials available

C15E + Al

STAINLESS STEEL - AISI304

STAINLESS STEEL - AISI316

Other materials on request

Surface treatments

Hot-dip galvanizing

Hot-dip galvanizing, one of the most popular methods of protecting steelwork from aggressive external weathering, is a process that applies a layer of molten zinc to the metal material. This treatment provides reliable and long-lasting protection, imparting corrosion resistance, cleanliness and luster to the artifact. Specifically, a hot-dip galvanizing thickness of about 78/86 microns ensures salt spray corrosion resistance of more than 250 hours. Due to its excellent protective properties, hot-dip galvanizing is widely used in industries such as shipbuilding, construction, and metal structure manufacturing, ensuring the preservation of the integrity and aesthetic appearance of metal components exposed to weathering and wear.

Galvanic zinc plating

Galvanic zinc plating, also referred to as electroplating, is a metal coating process that imparts strength, corrosion protection, cleanliness and luster to the material. This treatment involves immersing the metal object in a molten zinc solution or applying a layer of zinc by electroplating. Because of its protective and aesthetic properties, electroplating is widely used in industries such as construction, automotive, and shipbuilding to preserve the integrity and appearance of metal components exposed to weathering and wear.

Special threads on request

To ensure maximum adaptability to our customers’ specific needs, Osra Special Parts offers the option of customizing eyebolt threads. Whether for standard applications or special requirements, we are able to make special threads on demand to perfectly fit any usage scenario.

This flexibility allows us to support customers in a variety of industries, ensuring secure and reliable fastening. Customization of threads is carried out following the same.