Chain tensioner

Cutting-edge Solutions for Industrial Lifting

Looking for reliable and versatile solutions for your industrial lifting needs? At Osra Special Parts, we offer a wide range of chain tensioner, also known as anchor bolts or blocks, that meet the stringent specifications of ISO4347 for Fleyer chain users.

Chain tensioner are fundamental components for a variety of industrial applications, ensuring a solid connection between chains and lifting devices. We are dedicated to providing tailor-made solutions that meet the unique needs of our customers, offering high-quality and reliable products.

Chain tensioner are fundamental components for a variety of industrial applications, ensuring a solid connection between chains and lifting devices. We are dedicated to providing tailor-made solutions that meet the unique needs of our customers, offering high-quality and reliable products.

Bolt, block or both?

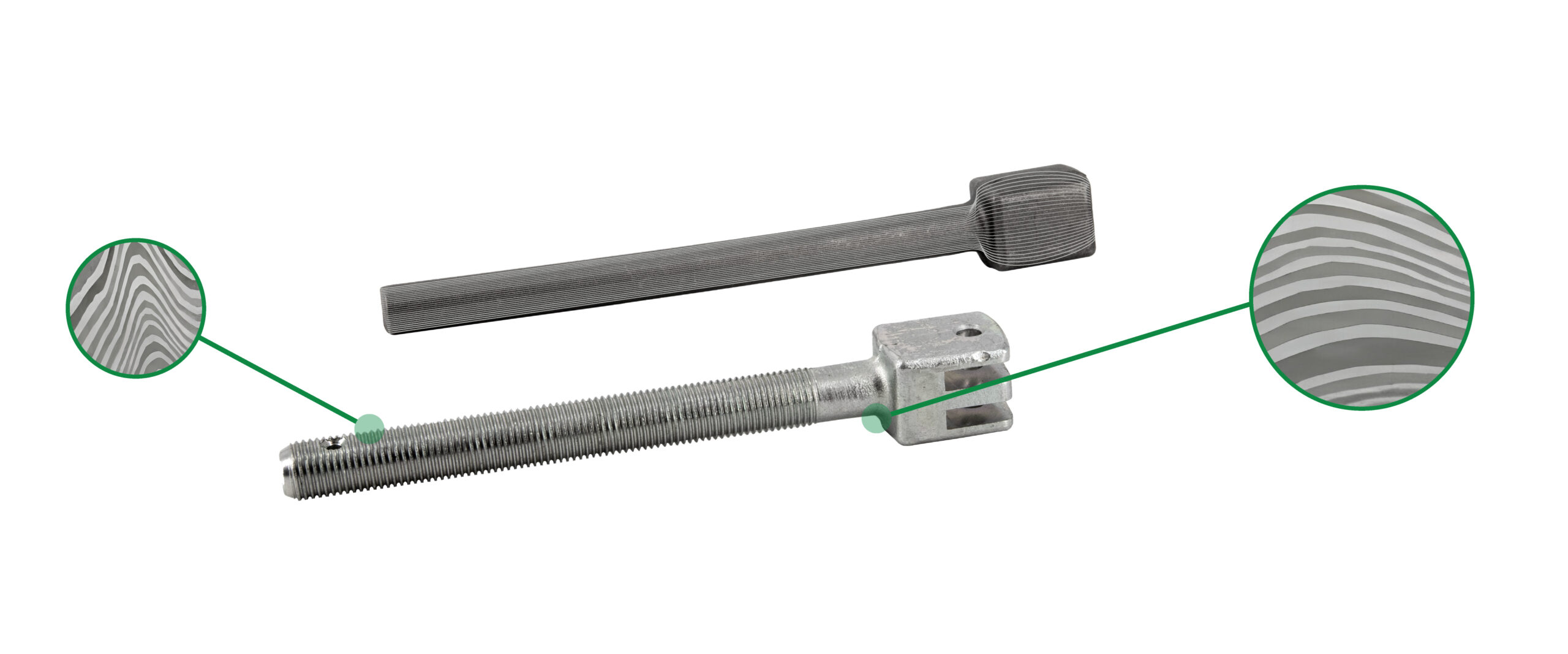

Chain tensioner are a versatile choice for a range of industrial applications, and among the available options, one can distinguish between adjustable and fixed chain slings. Adjustable chain slings offer the flexibility to adjust their length to suit various lifting situations. These components are often preferred for applications where length adjustment is crucial to ensure a secure and precise connection between lifting devices.

On the other hand, fixed chain slings are designed to fit into tight spaces, offering a robust and reliable solution for situations where the length of the tie rod is constant. Whether adjustable or fixed chain slings, at Osra Special Parts we are committed to providing high-quality products that meet the specific needs of our customers, ensuring safe and efficient lifting solutions.

On the other hand, fixed chain slings are designed to fit into tight spaces, offering a robust and reliable solution for situations where the length of the tie rod is constant. Whether adjustable or fixed chain slings, at Osra Special Parts we are committed to providing high-quality products that meet the specific needs of our customers, ensuring safe and efficient lifting solutions.

The electrical upsetting process process offers significant advantages both from a technical standpoint, providing greater mechanical strength and durability by keeping the material fibers intact, and from an economic standpoint, eliminating the need for material removal as is the case with tie rods produced from bar stock. Contact us to find out if your adjustable chain stays can be made with this technology.

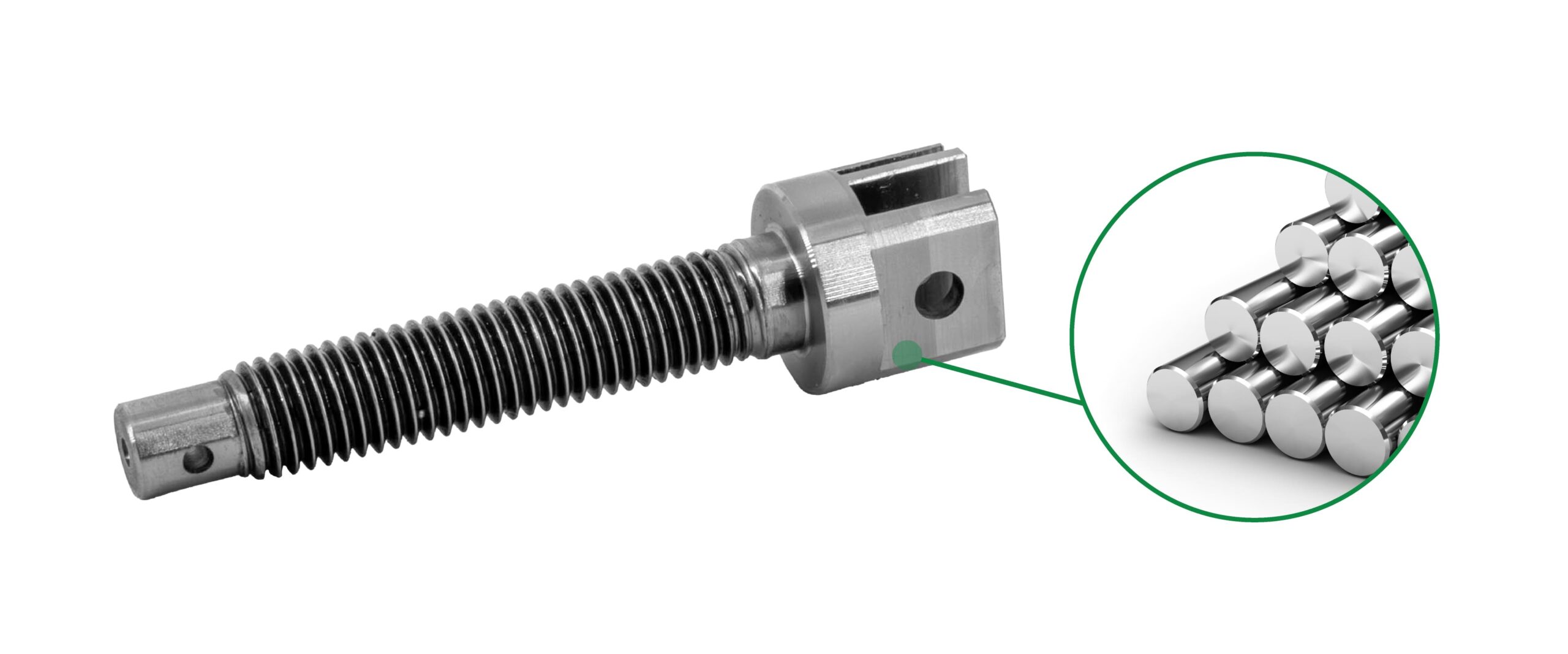

Where electrical upsetting technology is not applicable we can supply the anchor bolts stays machined from round bar. With this method, we can also supply the anchor blocks.

Available materials

42 CrMo4 - 39NiCrMo3

Quenched steel

INOX AISI 304 - 316 (A2 - A4)

DUPLEX

Upon request

Processing

Surface treatments

Burnishing

Burnishing is a surface treatment for metals that gives them a dark, corrosion-resistant finish. This process, often used to improve the appearance and durability of metal components, involves immersing the object in a chemical solution or applying a protective coating. It offers protection against oxidation and improves the appearance of the part by imparting a uniform and pleasing blue-black color. Burnishing is widely appreciated for its ability to create a surface that is resistant to weathering and wear, making it a popular choice for applications in industries such as automotive, furniture and manufacturing.

Galvanizing

Galvanizing, also referred to as electroplating, is a metal coating process that imparts strength, corrosion protection, cleanliness and luster to the material. This treatment involves immersing the metal object in a molten zinc solution or applying a layer of zinc by electroplating. Because of its protective and aesthetic properties, electroplating is widely used in industries such as construction, automotive, and shipbuilding to preserve the integrity and appearance of metal components exposed to weathering and wear.

Geomet

Geomet treatment is a nonelectrolytic anticorrosive process based on a patented aqueous solution. This technology, developed to protect metal surfaces from corrosion, offers numerous advantages, including weathering resistance and long service life. Geomet is particularly valued for its ability to provide reliable protection even in aggressive environments, making it an ideal choice for a wide range of industrial and commercial applications.

Phosphating

Phosphating is a chemical treatment that applies zinc or manganese phosphates to metals to protect them from corrosion. This process creates a protective layer on the metal surface, improving weathering resistance and preparing the surface for subsequent coatings such as paint or galvanizing. Widely used in industries such as automotive and manufacturing, phosphating ensures optimum durability and performance of metal components.

Special threads on request

We are able to meet specific needs by providing special threads on request for our chain tensioner. We understand that each industrial application may have unique requirements, and therefore we offer the flexibility to customize our products to fit our customers’ specific needs.

Special on-demand threads allow for greater versatility and adaptability of our chain tensioner, ensuring a tailored solution for every application. Rely on us to obtain chain tensioner that fully meet your needs, ensuring optimal performance and safety in any industrial setting.