Osra Special Parts is the ideal partner for industrial and mechanical processing, offering tailored solutions for sectors such as automotive, energy, and construction. Thanks to advanced technologies and high-quality standards, we provide a wide range of machining services ensuring optimal results, reliability, and precision.

Hot forging is a process that uses heat and pressure to produce complex, durable, and high-quality parts for the earthmoving and lifting sectors. We work with various metals and guarantee customized solutions to meet our clients’ needs. Our advanced technology ensures consistent and long-lasting results while maintaining a high standard of quality.

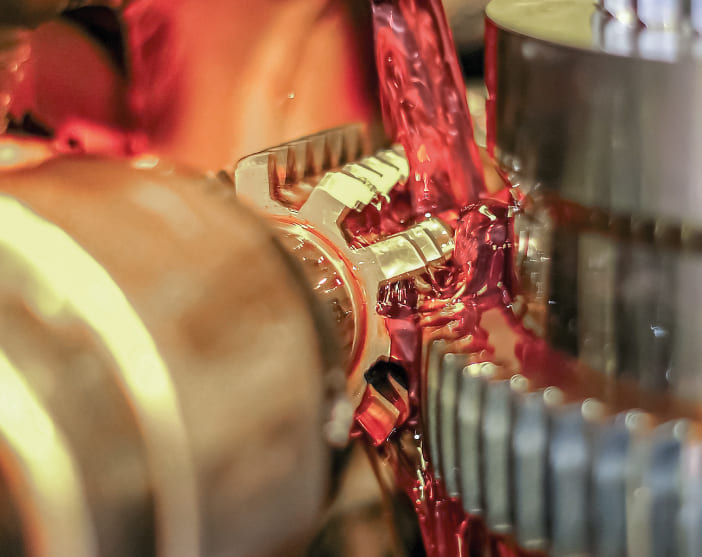

Cold forging uses electric current to heat and deform metal precisely, preserving fiber integrity for enhanced mechanical strength. Ideal for components used in lifting and automotive applications, it guarantees tight tolerances and reliable performance.

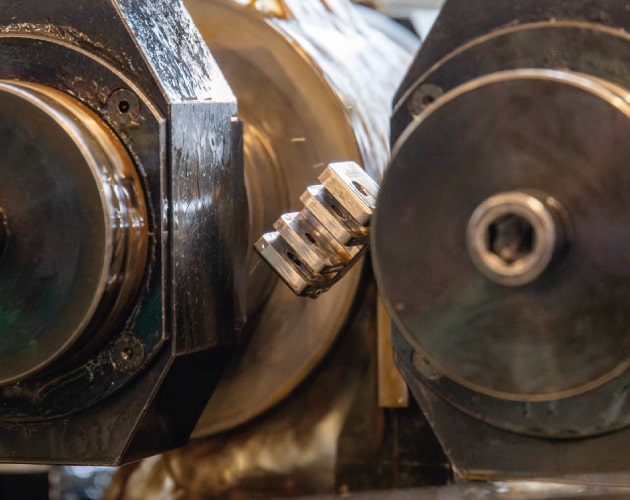

Machining from solid bar stock allows the production of precise and customized components starting from solid metal bars. This technology is employed in sectors such as automotive, pharmaceutical, and precision mechanics, ensuring robust and uniform parts with strict quality control.

A surface treatment that provides metals with a dark finish resistant to corrosion and wear. This chemical or protective process creates a uniform black-blue coating, improving aesthetics and durability. Used in automotive, furniture, and manufacturing sectors for its resistance to weathering and abrasion.

Galvanic (electrolytic) zinc plating coats metals with a layer of zinc through immersion in molten zinc or electrodeposition, enhancing resistance, corrosion protection, and shine. Widely used in construction, automotive, and shipbuilding to preserve the integrity and appearance of metal components exposed to atmospheric agents and wear.

Geomet treatment is a non-electrolytic anticorrosive process based on a patented aqueous solution offering numerous benefits such as weather resistance, long-lasting protection, and reliable performance even in aggressive environments.

Phosphating is a chemical treatment applying zinc or manganese phosphates to metals to protect them from corrosion. It creates a protective layer on the metal, improving resistance to atmospheric agents and preparing the surface for subsequent coatings like paint or zinc plating. It ensures durability and optimal performance.

Every industrial application has unique requirements; therefore, we offer custom special threads upon request to ensure maximum compatibility with your lifting systems.

Our team is available to advise you on the best solution for your lifting needs

Esperti nell’industria meccanica, siamo leader nella produzione di componenti specializzati per un’ampia gamma di settori, dal sollevamento industriale alla tecnologia automobilistica, al movimento terra e all’energia.

Partita IVA: 03626670131 / REA: 413416 / Capitale Sociale: €127.000.00 i.v